B2 Size Digital Production Press Inkjet Printer

FujiFilm Jet Press 750 / 750s

|

|

Jet Press 1160CF High-speed Continuous Feed Inkjet Printing System Printing with a high level of productivity and quality. The highest printing density in the industry (in 160 m/min continuous paper inkjet printer class) |

HIGH PERFOMANCEThe printer can print in full colour at a maximum speed of 160 m/min, which is equivalent to 2,096 pages per minute on precut A4 paper*2.

Mass batch prints of tens of thousands of pages may be created at high speeds through the use of the unwinder and rewinder*3

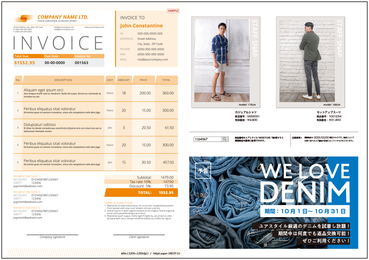

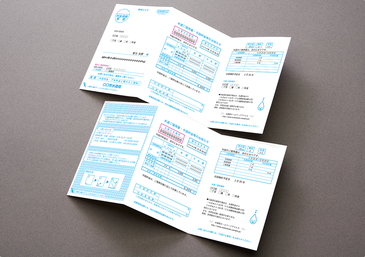

This ensures great productivity and stable processing for high-volume/short-duration print jobs such as trans-promo materials and invoices.

- *1: Speed priority mode (1,200 x 600 dpi)

- *2: Two-sided printing with dual layout of A4 pages

- *3: Optional

HIGH QUALITY

Pigment Inks with High Concentrations

Superior image quality printing is achieved through the newly designed high-concentration pigment ink.

High-quality, high-definition prints up to 1,200 x 1,200 dpi

Printer can produce output image with great resolution:

- 1,200 x 600 dpi (with a print speed of 160 m/min)

- 1,200 x 1,200 dpi (with a print speed of 80 m/min)

It prints characters and numbers clearly.

FAST DATA PROCESSING

Print server featuring Fujifilm Business Innovation's unique technology provides high quality output and rapid processing.

FAST DATA PROCESSING

Print server featuring Fujifilm Business Innovation's unique technology provides high quality output and rapid processing.

- Faster On-the-fly*1 printing

- High quality image data processing 1,200 x 1,200 dpi, 8 bit

- Supporting APPE*2 perfect for PDF output

- High-precision CMYK profiles

- High-speed, large volume printing of variable data

(Mercury RIP, Industry standard PPML, PDF/VT-1, PDF/VT-2) - Increased fault tolerance due to OS HDD redundancy

- Uninterruptible power supply (UPS)*3

- *1: Requires direct printing without creating raster data in advance.

- *2: Adobe® PDF Print Engine

- *3: A product sold by Fujitsu. Two units are required.

INSIDE STRUCTURE

- Print Head Box

The print head supports 1,200 x 1,200 dpi printing.

A single dot can be expressed with up to three gradations, allowing for smoother density transitions. - Dryer

Two types of drying technology is utilised: heat drum and heat air dryers. - Unwinder

It can be configured to feed paper with roll positioned for top or bottom feeding.

Raising and lowering heavy paper rolls is performed through a simple mechanism. Paper alignment can be applied rapidly through a simple interface. - Rewinder (Optional)

The machine can wind paper either upwards or downwards. A touch roller is added to prevent wrinkling when rewinding. - Tension Controller

It assures that paper tension remains constant, helping to stabilise paper feed during high-speed printing. - Edge Guide

Paper movement, positioning, monitoring allows for adjustment to remove any misalignment of the paper path which allows for a smooth printing process. - Operation PanelMachine operation is via a simple touch screen interface.

- Cart Ink Pack

The four-colour ink packs are located on the back of the printer. Ink packs weigh about 20 kg per colour. Replacement is performed easily using a specialised cart. - Inspection Box (Optional)

This is the box for inspection unit for example.

Different kinds of inspection boxes and units are available depend on countries.- Note: Contact with our sales representative for details.

- ChillerThe chiller flows water through the printer to cool the paper.

Slack Web Unit (Optional)

This unit applies tension to roll paper when not using the rewinder. Users can utilise a post-processing device with a loose tension.

Printer configuration |

Twin Engine Duplex |

Colour capability |

Full Colour |

Printing method |

Piezoelectric drop-on-demand inkjet method |

Printing resolution |

Image Quality Priority : 1,200 x 1,200 dpi Speed Priority : 1,200 x 600 dpi |

Halftone |

3 levels per drop |

Warm-up time*1 |

15 minutes or less (when the room temperature at 23°C) |

Continuous print speed |

Image Quality Priority : 80 m/minutes (1,048 ppm*2) Speed Priority : 160 m/minutes (2,096 ppm*2) |

Paper size*³ |

Width 152.4 to 520.7 mm |

Paper weight*4 |

64 to 250 gsm |

Paper feed |

Unwinder connected (maximum roll diameter: 1,270 mm) |

Paper discharge |

Rewinder*5 connected (maximum roll diameter: 1,270 mm) |

Feeding speed |

Maximum 160 m/minutes |

Operating Noise*⁶ |

In operation: 79 dB(A) |

Power supply |

Three-phase AC200 V +/-10 %, 200 A, 50/60 Hz common (Printer) Three-phase AC400 V +/-5 %, 200 A, 50/60 Hz common (Printer) |

Maximum Power consumption |

26.3 kW (Three-phase AC200 V), 127.0 kW (Three-phase AC400 V) |

Dimensions*⁷ |

W8,600 x D2,482 x H1,880 mm (With rewinder) W7,800 x D2,482 x H1,880 mm (With slack web unit. Without rewinder) |

Installation space*⁷ |

W12,600 x D5,700 mm (With rewinder) W11,820 x D5,700 mm (With slack web unit. Without rewinder) |

Weight*⁷ |

9,337 kg (With rewinder) 8,887 kg (With slack web unit. Without rewinder) |

Jet Press 1160CF Brochure

| jet_press_1160cf_brochure.pdf |